In an era where environmental sustainability is more than just a buzzword, advanced polymers are playing a pivotal role in revolutionizing the design and manufacturing processes across various industries. These innovative materials offer a multitude of benefits, ranging from enhanced durability and versatility to significant reductions in environmental impact. By understanding the properties and applications of advanced polymers, we can appreciate their integral role in promoting sustainable design and contributing to a greener future.

One of the primary advantages of advanced polymers is their lightweight nature, which reduces the energy required for transportation and processing. This is particularly important in the automotive and aerospace industries, where weight reduction directly correlates with fuel efficiency and, consequently, lower greenhouse gas emissions. Polymers like carbon fiber-reinforced plastics (CFRP) and thermoplastic composites are increasingly used to replace heavier metal components, leading to vehicles and aircraft that are not only more fuel-efficient but also exhibit improved performance characteristics.

Another significant benefit of advanced polymers is their ability to be engineered for specific applications. Unlike traditional materials, polymers can be synthesized with properties tailored to meet precise requirements, such as high tensile strength, flexibility, or resistance to chemicals and UV radiation. This level of customization allows designers to optimize the material’s performance while minimizing waste. For example, in the construction industry, polymer-based materials like fiber-reinforced polymer (FRP) composites are used to create lightweight, corrosion-resistant structures that require less maintenance and have longer lifespans compared to conventional materials like steel or concrete.

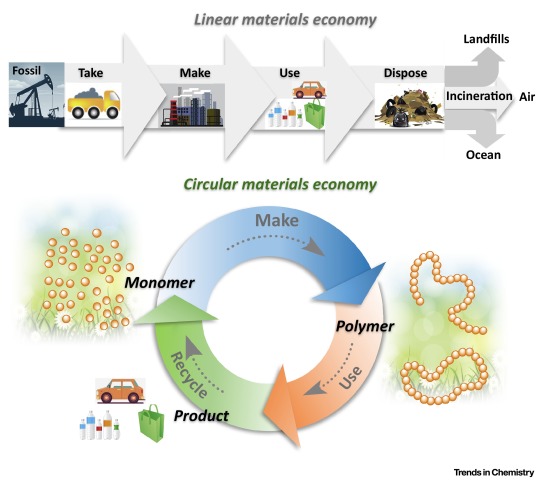

Moreover, the recyclability of many advanced polymers contributes to their sustainability credentials. Polymers such as polyethylene terephthalate (PET) and high-density polyethylene (HDPE) are commonly recycled into new products, reducing the demand for virgin materials and lowering the environmental footprint of production processes. Innovations in polymer recycling technologies, such as chemical recycling, are further enhancing the efficiency and feasibility of recycling more complex polymer blends, thereby supporting a circular economy where materials are continuously repurposed and reused.

One noteworthy example of advanced polymers in sustainable design is the development and use of biopolymers. Derived from renewable resources such as corn starch, sugarcane, or cellulose, biopolymers offer a sustainable alternative to petroleum-based plastics. Polylactic acid (PLA), for instance, is a biopolymer that is not only biodegradable but also possesses properties comparable to conventional plastics. Its applications range from packaging and disposable cutlery to medical implants and 3D printing, demonstrating its versatility and potential to reduce plastic waste.

In addition to their environmental benefits, advanced polymers also play a crucial role in enhancing the functionality and aesthetic appeal of sustainable designs. Polymers can be formulated to incorporate a variety of additives that impart unique properties, such as flame retardancy, antimicrobial activity, or self-healing capabilities. These enhancements not only extend the lifespan of products but also reduce the need for additional treatments or coatings, which can be harmful to the environment.

A prime example of the intersection of functionality and sustainability in polymer use is seen in the production of nylon 6 sheet. Nylon 6, known for its excellent mechanical properties, wear resistance, and chemical stability, is utilized in a wide array of applications, from automotive parts to industrial machinery. Its durability and ability to be recycled into new nylon products make it a valuable material in sustainable design. The use of nylon 6 sheet in manufacturing durable goods helps extend product life cycles, thereby reducing the frequency of replacements and the associated environmental impact.

The role of advanced polymers in sustainable design extends beyond their material properties to include their impact on energy consumption and resource efficiency during manufacturing processes. For instance, injection molding of polymers typically requires lower processing temperatures and less energy compared to metal casting or machining. This not only reduces energy consumption but also lowers the carbon footprint of the production process. Additionally, advancements in polymer processing techniques, such as additive manufacturing or 3D printing, allow for the creation of complex geometries with minimal material waste, further enhancing resource efficiency.

Furthermore, the integration of advanced polymers into smart materials and structures opens new possibilities for sustainable design. Smart polymers, which respond to environmental stimuli such as temperature, light, or pH, can be used in applications ranging from self-regulating insulation systems to adaptive clothing. These materials offer the potential for dynamic, energy-efficient solutions that can adapt to changing conditions, thereby reducing the need for external energy inputs and enhancing overall sustainability.

In conclusion, advanced polymers are indispensable in the pursuit of sustainable design. Their unique properties, recyclability, and versatility enable the creation of innovative solutions that address environmental challenges while improving performance and functionality. By continuing to explore and expand the applications of these materials, we can pave the way for a more sustainable future, where resources are used more efficiently, waste is minimized, and the environmental impact of human activities is significantly reduced. The ongoing development and integration of advanced polymers into various industries underscore their critical role in shaping a sustainable world.